Finishing, Assembly & Value-Add

The ultimate point of the entire production process is when your item finally gets its full condition. Finishing, Assembly, and Value-Add services we provide guarantee that the production of each separate component not only fits the requirements dictated by the measurements but also has the looks, sensations, and the performance characteristics that work as intended. The detailing that transforms molded parts into finished goods is our responsibility.

The ultimate point of the entire production process is when your item finally gets its full condition. Finishing, Assembly, and Value-Add services we provide guarantee that the production of each separate component not only fits the requirements dictated by the measurements but also has the looks, sensations, and the performance characteristics that work as intended. The detailing that transforms molded parts into finished goods is our responsibility.

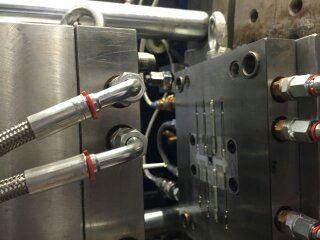

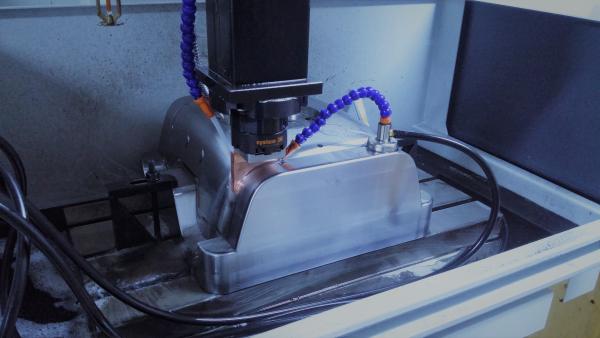

The capabilities for the finishing embrace a number of different processes that are adjusted to the client's needs. We perform ultrasonic welding, heat staking, CNC trimming, tapping, and laser marking which result in very precise and repeatable outcomes that improve the function and appearance of the product at the same time. Pad printing and custom painting can be used for branding purposes by adding logos, graphics, or surface textures that not only strengthen your brand identity but also give a neat final impression.

The production department is sometimes where the combination of quality and efficiency gets realized. There is a wide range of services such as light mechanical assembly, sub-component assembly, kitting, and packaging that we offer which only require you to make one call to us. Our technicians put together every piece with precision and attention to detail no matter if your product consists of several fasteners, snap-fit connections, or integrated electronics.

We are aware of the fact that traceability and consistency are extremely important, especially for regulated or high-value items. The inspections and paperwork performed on every finished product are of such intensity that they confirm conformity with your quality requirements. Our checks include visual inspections, dimensional measurements, and functional testing where appropriate—so you can trust that your parts will be ready for the line and free of defects.

Through every step of the process, from the very first molded part to the last packaged product, our goal is to always the same: to provide reliable, ready-for-production parts that not only simplify your work but also enhance the strength of your final product. You are free to go through the entire product development process with assurance, effectiveness, and total relaxation if you take advantage of our finishing, assembling, and adding value to services.

Hear From Our Customers

Feedback from the companies we work with. Discover their experiences and contact to discuss how we can support your next project.

They guided us through the tooling stage with patience and clear updates. The first production run went smoothly.