Injection Molding

Injection molding contours are our hallmark, and we orchestrate them in a manner that your product imagination becomes a reality through accuracy, aikido, and cost-effectiveness. Whether it is just a few units for prototyping or thousands of units for production, we cater to all requirements by supplying molded parts that not only fit the exacting standards but are also able to endure the toughest applications for years. Every project is supported by our extensive technical knowledge, careful process control, and the pursuit of perfection.

Injection molding contours are our hallmark, and we orchestrate them in a manner that your product imagination becomes a reality through accuracy, aikido, and cost-effectiveness. Whether it is just a few units for prototyping or thousands of units for production, we cater to all requirements by supplying molded parts that not only fit the exacting standards but are also able to endure the toughest applications for years. Every project is supported by our extensive technical knowledge, careful process control, and the pursuit of perfection.

We mix different types of plastics and other resins, which makes it possible for us to create extremely light parts with great strength and flexibility. Our process ranges from producing clear lenses to making the outer shells of machines to creating tiny parts of a machine that need to work precisely; we do so by customizing it according to your design and usage needs.

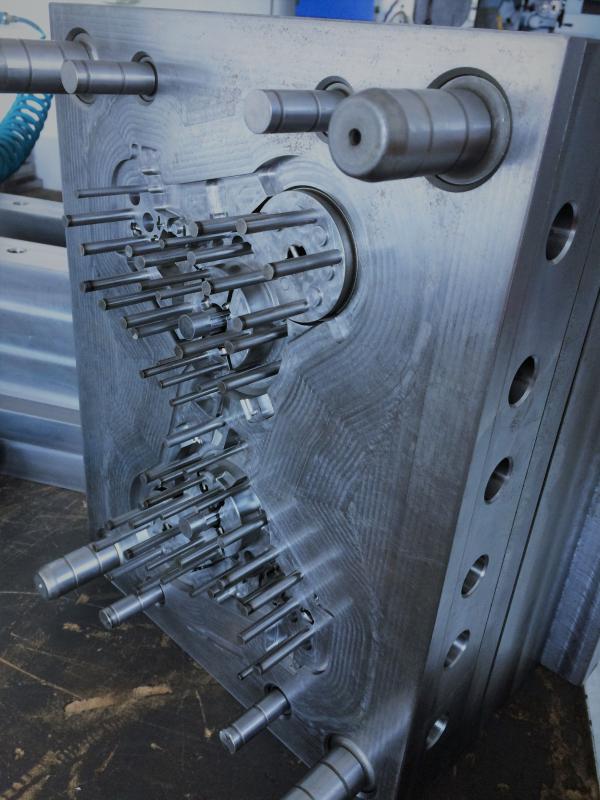

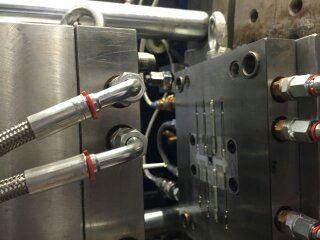

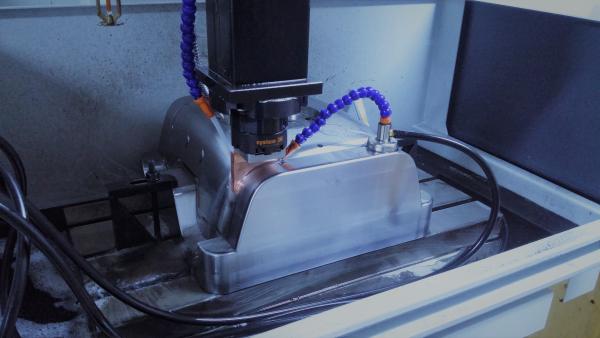

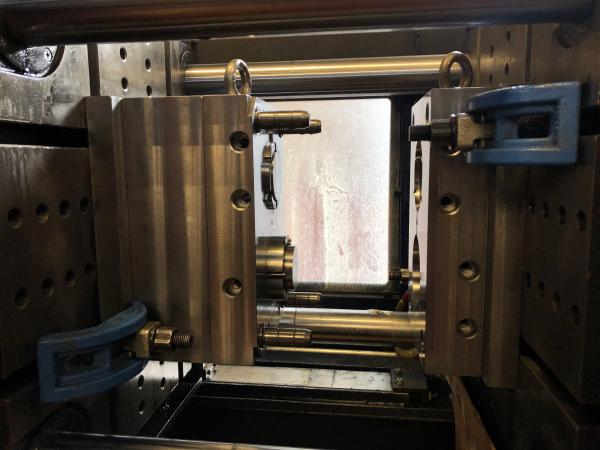

The workshops of our foundries are fitted with high-performance machines that are cutting-edge in technology and produce shot after shot with reproducible accuracy. A seasoned technician sets up each mold, and he/she certifies it after testing the parameters of pressure, temperature, and cycle time to make sure that the quality is consistent. Inspection during the process and automatic systems help in identifying problems before they escalate and thus, minimizing the time lost during such problems.

Our molding philosophy emphasizes flexibility above all else. We are capable of producing small quantities of specialty or special products as well as running high-volume production where cycle time and productivity are major concerns. For intricate parts or assemblies, we give the choice of insert molding and overmolding which combines the use of two or more materials or components into a single, integrated solution.

Quality is incorporated into every step of the process. We apply extensive inspection plans, dimension checks, and performance testing to ensure that each part is compliant with your requirements. In addition, our engineers collaborate with you to ensure that your parts are not only precise, but also economical to manufacture and convenient to assemble in the future.

We use advanced technology, trained personnel, and responsive engineering support to set up a molding process that meets your targets—whether it is introducing a new product, expanding production, or improving an existing design. The point to keep in mind is quite clear: reliable molded parts, delivered on schedule, and ready for your next step towards success.

Hear From Our Customers

Feedback from the companies we work with. Discover their experiences and contact to discuss how we can support your next project.

They guided us through the tooling stage with patience and clear updates. The first production run went smoothly.